Concrete weight pipe coating

Concrete weight pipe coating equipment

Specifications taken into account when designing the concrete weight pipe coating equipment are API 5L 44th Edition, BS-1881, BS-12, BS 4027, ASTM C150, BS-882, ASTM C33, DNV-OS-F101/2000.

Impingement or wrap coating

An impingement concrete weight coating plant applies concrete using high-speed rollers that spray the mix onto the rotating pipe surface as it passes the station. In a compression coating plant, the pipe moves helically past an applicator belt that presses the concrete and wire mesh layers onto the pipe wall, after which rotating belt heads carry it forward. Bauhuis has introduced several innovations to improve impingement plant efficiency, including a continuous coating carrousel, an automatic wire mesh applicator, and a reclaim system that reduces spillage and overspray.

Concrete batch plant

To produce the concrete weight coating mix with the correct density, iron ore, sand, cement, and water are blended in batch plants supplied with the coating system. These plants include cement silos, sieving and weighing bunkers, transport belts, and heavy-duty mixers. The finished mix is discharged into the hopper before the application head. Reclaim systems enable reuse of overspray, maximizing plant efficiency.

Reinforcement types

All concrete weight coatings require reinforcement, using either steel cages (for impingement systems), steel wire mesh, or a combination. The number of mesh layers depends on the final coating thickness up to 200 mm and the required reinforcement percentage.

Anodes

For mounting anti-corrosion anodes, Bauhuis supplies complete installation stations with rotators, jib cranes, welding units, and backfill equipment.

Curing

Curing methods vary with climate. In hot regions, pipes are wrapped in plastic and cured outdoors; in cold conditions, they are placed in steam-heated curing cabins. Bauhuis has extensive expertise in designing and constructing these specialized curing systems.

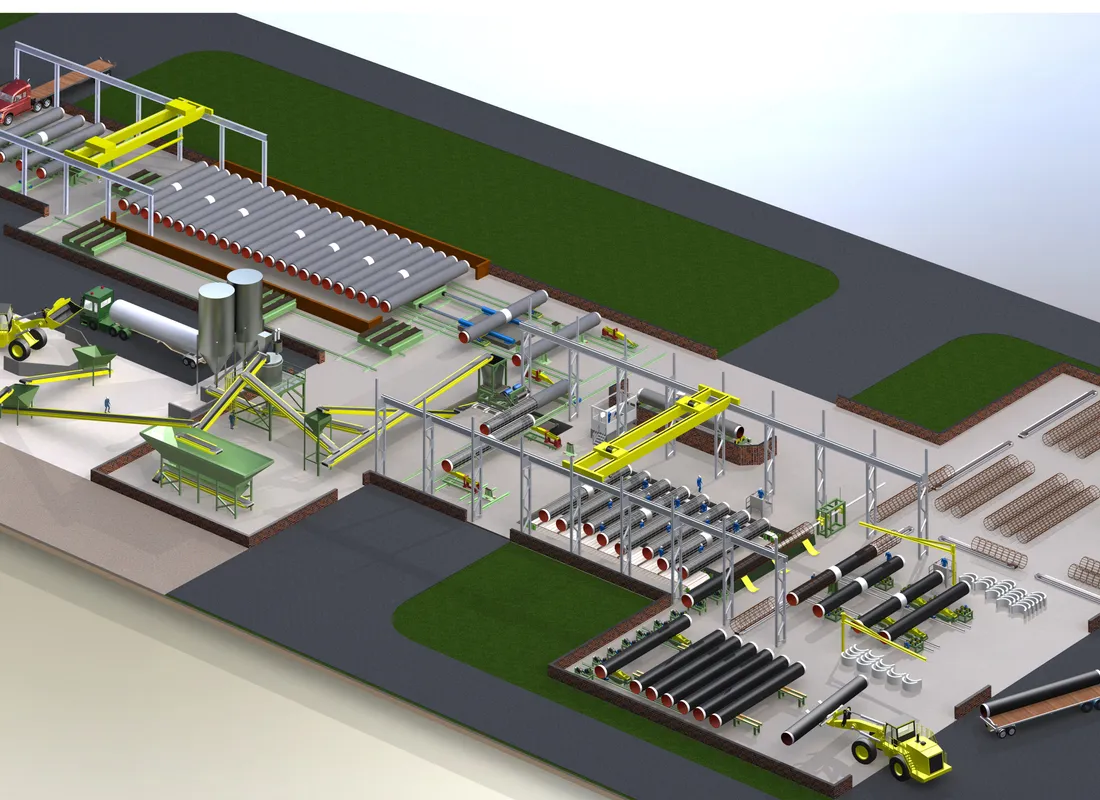

Concrete weight pipe coating plant

External concrete weight coating on pre-coated steel pipes provides both negative buoyancy and mechanical protection. The coating thickness depends on the pipeline’s operating depth. There are two main types of coating plants: impingement and compression (wrap) systems.

The illustration on the left shows the standard layout of a concrete weight pipe coating plant.