Double joint & spoolbase

Double joint equipment

Bauhuis designs and supplies complete double jointing systems for welding single pipe joints (12 m) into double joints (24 m), quad joints (48 m), or full pipe strings up to 1,200 meters in length. These systems are used by onshore double jointing facilities, spoolbase plants, and offshore pipe-laying vessels.

In collaboration with trusted partners, Bauhuis can integrate pipe welding equipment, internal line-up clamps (ILUCs), NDT stations, and X-ray tunnels into the overall setup.

Line-up cars

The line-up cars in the initial station of a double joint or spoolbase plant are essential for accurate alignment and a strong first weld. Bauhuis designs these cars with full hydraulic control systems and high-precision proportional valves to ensure maximum accuracy and productivity. Models can be equipped with endo rollers for offshore or spoolbase use, or with servo-driven rotation units for precise pipe movement.

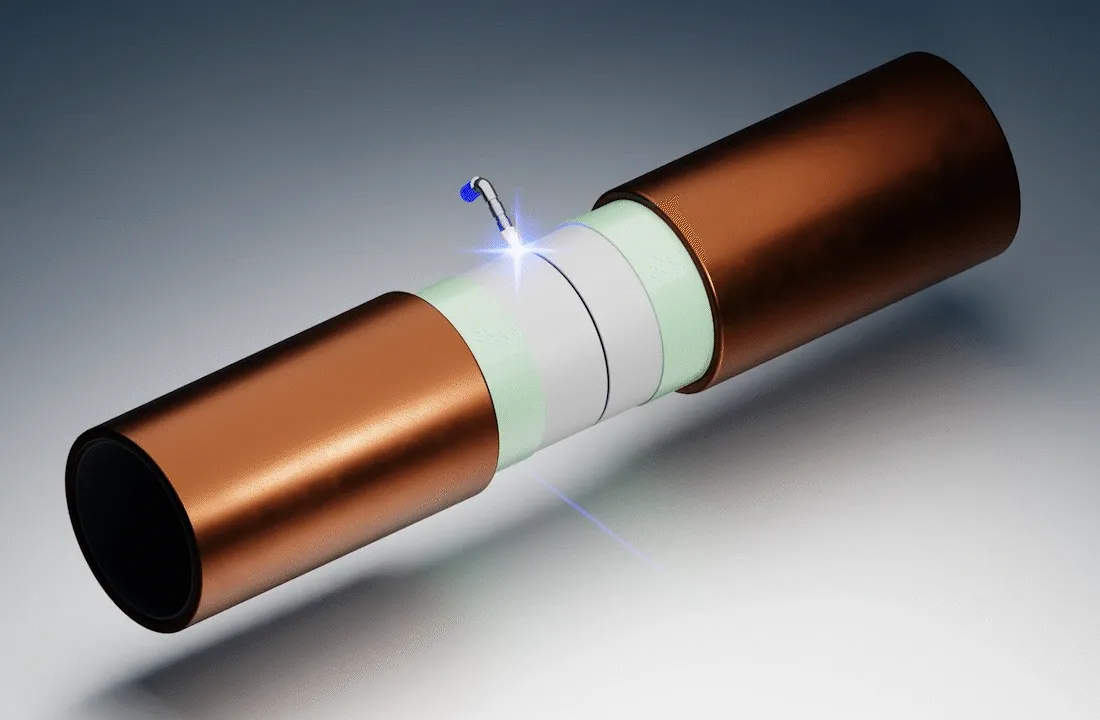

Blasting & coating frames

To prepare and protect the welded pipe ends, Bauhuis provides automated blasting and coating frames. Depending on the project requirements, systems can include induction heating coils, automated blasting frames, FBE powder coating units, and MLPP injection coating stations ensuring a durable and uniform finish for every joint.

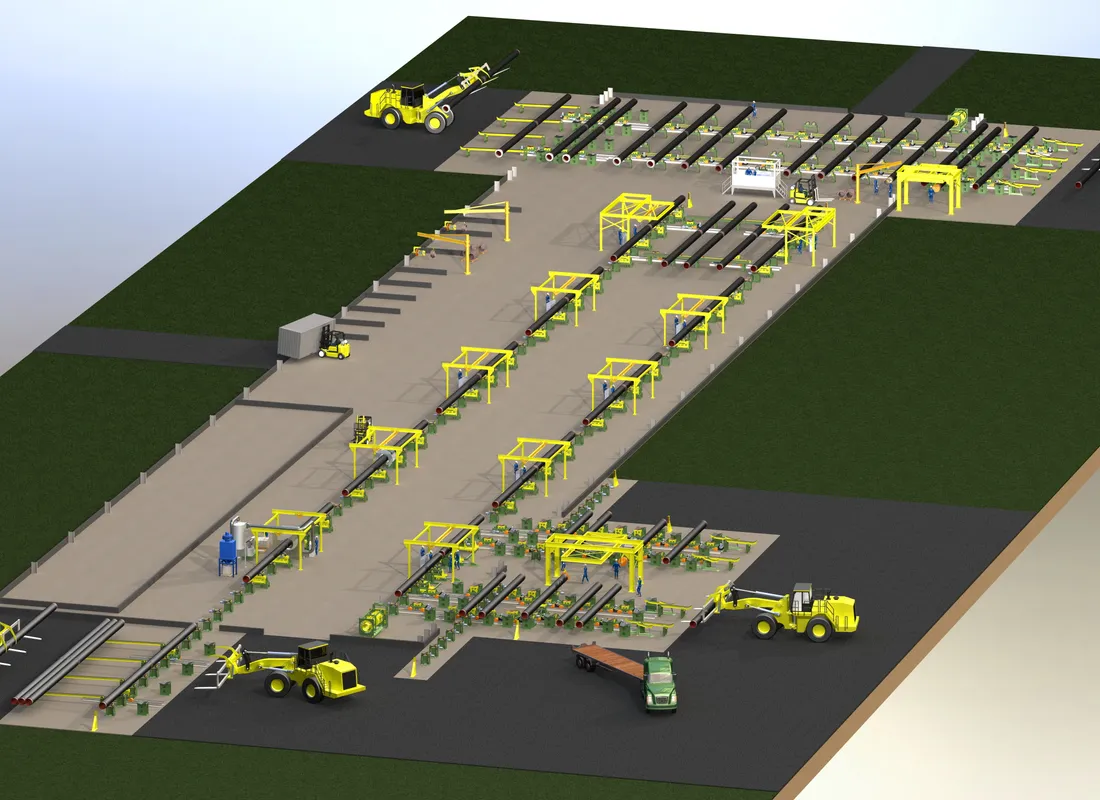

Double joint & spoolbase plants

Bauhuis supplies complete pipe handling equipment packages for Double Joint and spoolbase plants. These systems can include fully automated incoming and outgoing pipe racks, pipe pushers, line-up cars, handling buggies, rotators, and endo or double-wheel conveyors.

Field joint coating equipment for blast cleaning and coating applications can also be integrated into the setup.

The image on the left shows the standard layout of a Double Joint or spoolbase plant.