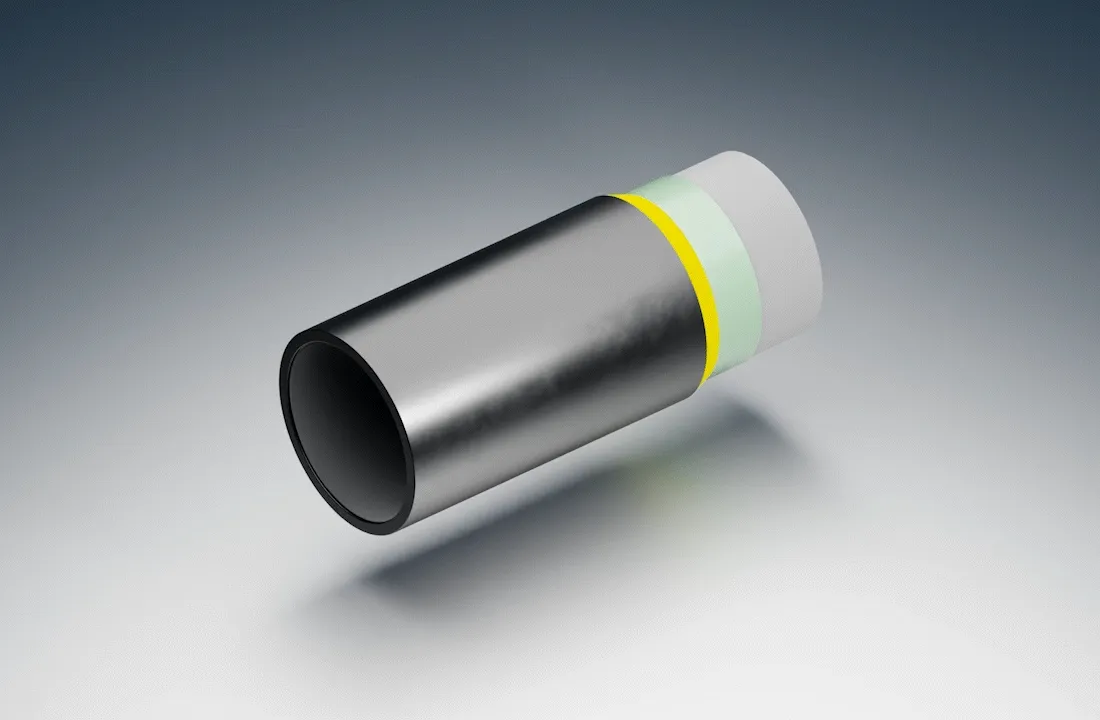

External pipe coating

External pipe coating equipment

The three-layer anti-corrosion coating system combines advanced external pipe coating equipment and proven protective materials. It starts with a high-performance fusion bonded epoxy (FBE) layer, followed by an adhesive copolymer or intermediate bonding layer, and is finished with an outer layer of polyethylene (PE) or polypropylene (PP).

This complete coating system ensures long-lasting corrosion resistance and durable mechanical protection, even under demanding environmental conditions. All coating applications are performed in full compliance with international standards, including CAN/CSA-Z245.21, NFA 49-710, DIN 30670–30678, and EN 10285.

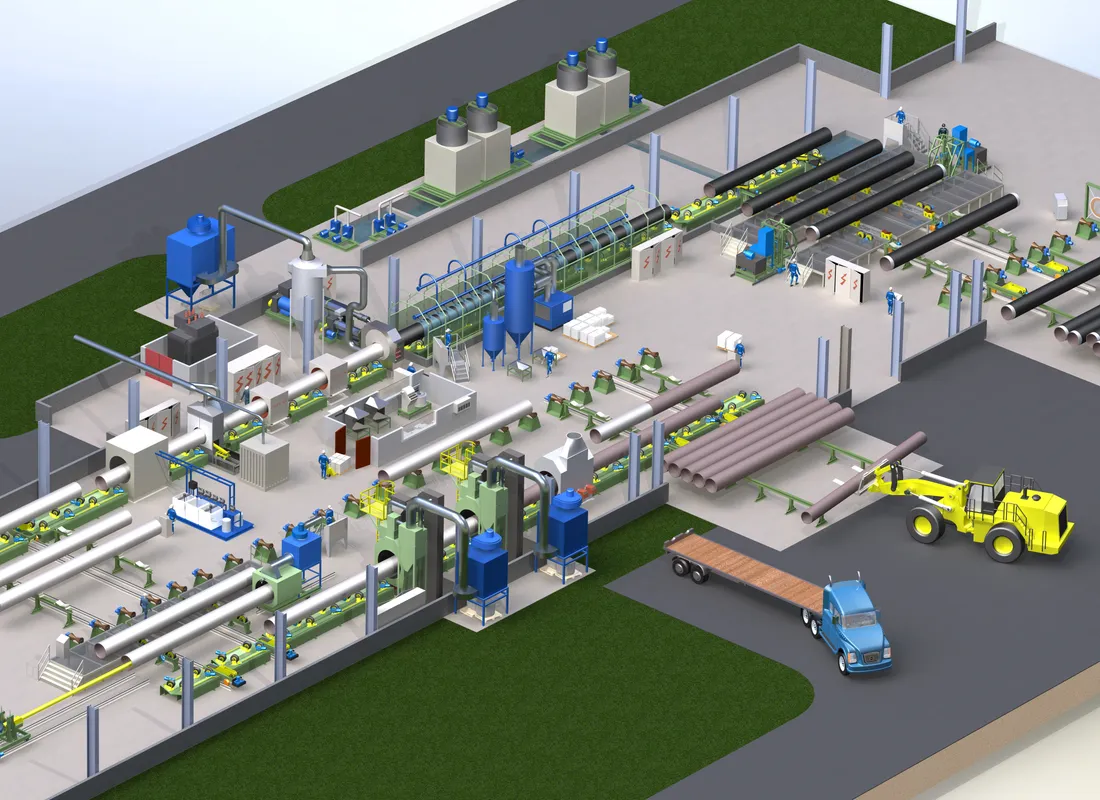

External pipe coating plants

Depending on the required output and available space, Bauhuis designs and delivers turnkey external pipe coating plants for three-layer coating systems on pipes ranging from 4” to 120” in diameter.

Each plant can include pre-wash and pre-heat systems, external blasting units, phosphoric acid and chromate treatment stations, induction heating, FBE and adhesive application equipment, PE extrusion, quenching, end-cleaning, and full inspection systems to ensure coating integrity.

The diagram on the left shows a standard Bauhuis three-layer external pipe coating plant.

External pipe blasting equipment

The Bauhuis external pipe blasting system is a fully enclosed, high-performance unit designed to clean the outer surface of steel pipes with precision and consistency. Each machine features turbine wheels powered by electric motors and an internal hardened steel lining to minimize wear and reduce maintenance needs. An integrated blast media reclaim system cleans and recycles abrasive material through an elevator and air-wash extraction process for continuous, efficient operation.

All Bauhuis blasting systems achieve the highest surface cleanliness levels — SIS SA 3 / ISO 8501-1 / SSPC-SP-5 — ensuring optimal coating adhesion and surface quality. Equipment design meets international standards including API 5L (44th Edition), ISO 8501-1, ISO 8502-3, and ASTM D4940.

Reliability that lasts

With equipment costs representing only a small part of total plant expenses, reliability and efficiency are key to long-term success. Bauhuis systems are engineered for consistent, high-quality output throughout the plant’s lifetime. Many installations from the early Bauhuis years are still in operation today — a testament to their proven durability and performance.

Pipe handling equipment

Automated pipe handling is essential for modern coating plants. Bauhuis pipe handling systems combine robust mechanical engineering with advanced power and control systems, enabling safe, efficient, and fully automated pipe movement throughout the coating process.