Internal pipe coating

Internal pipe coating equipment

Steel pipes used for the transport of oil, gas, or water are internally coated to enhance flow efficiency and prevent corrosion. Flow efficiency coatings typically have a dry film thickness between 75 and 100 microns, while anti-corrosion coatings can reach up to 1000 microns.

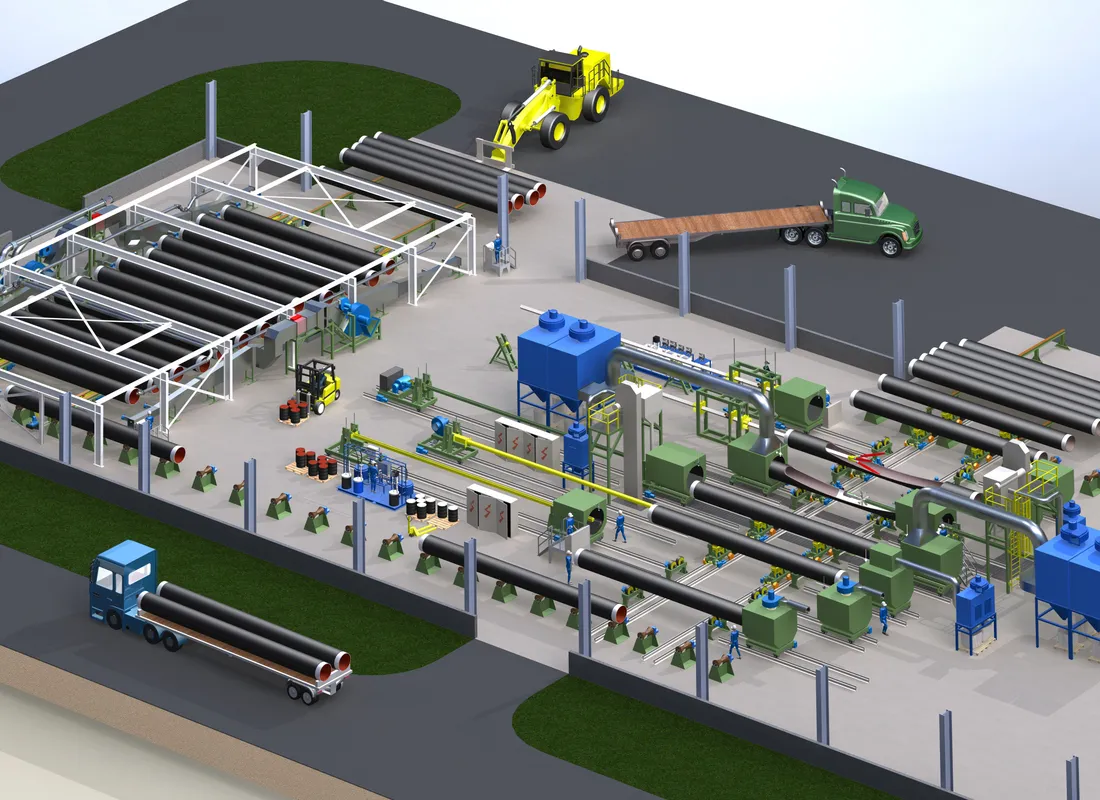

Bauhuis provides turnkey solutions for the internal coating of pipes ranging from 2″ to 140″ in diameter. Our complete coating plants include all essential equipment for every stage of the process from internal degreasing, preheating, blasting, and blow-out, to coating application and curing.

Each system is equipped with advanced pipe handling technology to ensure smooth transport between process stages, with options for manual control or fully automated operation for maximum efficiency and reliability.

Leading in internal pipe coating solutions

With over 50 internal pipe coating plants operating worldwide, Bauhuis is a global leader in pipe coating and blasting technology. Our hydraulic-powered internal blasting turbine is one of our signature designs, cleaning up to 500 m² per hour to an SA 2.5 surface cleanliness level.

Each Bauhuis coating plant is engineered for efficiency and reliability, including pre-wash, pre-heating, internal blasting, blow-out, coating application with fume treatment, curing, and inspection.

The diagram on the left shows a standard Bauhuis internal pipe coating plant for liquid epoxy coating.

Internal pipe blasting equipment

Achieving a flawless internal coating starts with excellent surface preparation. The Bauhuis hydraulic-powered blasting turbine, one of our flagship innovations, delivers consistent cleaning performance up to 500 m² per hour, meeting SA 2.5 / ISO 8501-1 / ISO 8503-2 standards. For smaller pipes under 12.75”, air blast stations are available to achieve the same high-quality result.

Each Bauhuis blasting system is built for efficiency and durability, with pre-cleaning and pre-heating options to remove contaminants and moisture. An integrated blast media reclaim system ensures clean, recycled abrasive use for continuous, cost-effective operation delivering reliable performance in demanding industrial environments.

Cement mortar lining & internal FBE coating

In addition to liquid epoxy systems, Bauhuis designs and supplies complete plants for cement mortar lining (commonly used for water pipelines) and internal FBE coating using fusion-bonded epoxy powder. Each installation is engineered to meet AWWA C210, C213, C205 or specific client standards, ensuring reliable performance and long-term corrosion protection.

Pipe handling equipment

Automated pipe handling is essential for safety and efficiency in modern coating plants. Bauhuis pipe handling systemscombine robust mechanical construction with advanced power and control technology, enabling smooth, hands-free movement of pipes throughout the entire coating process.