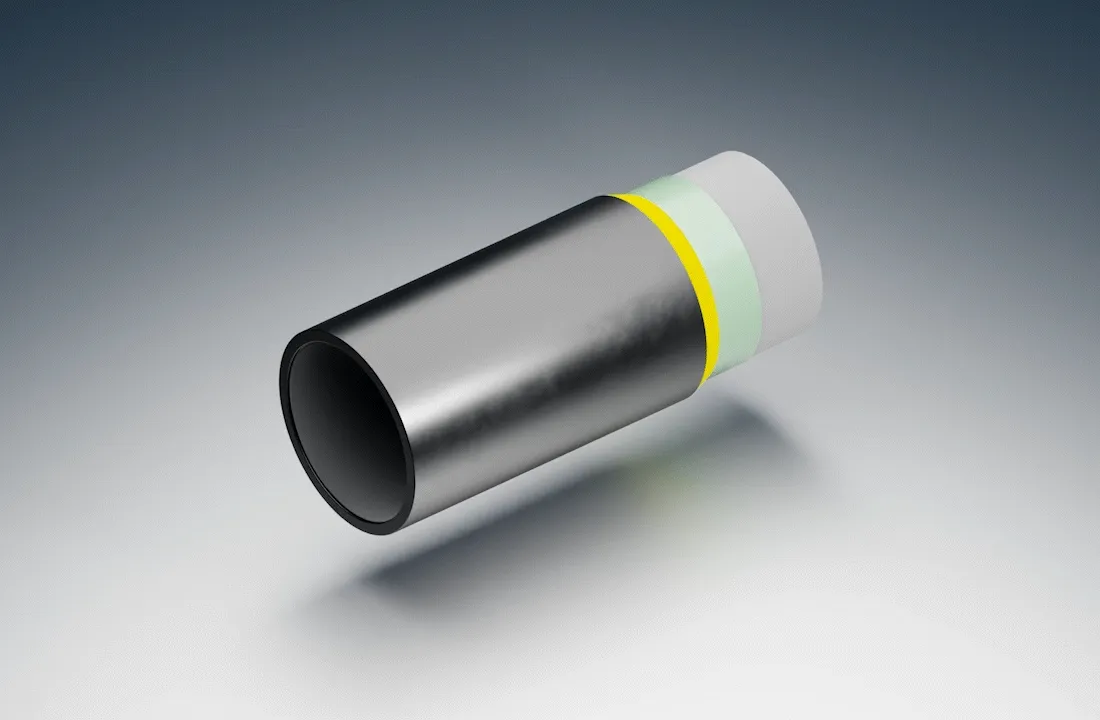

PU pipe coating

Polyurethane (PU) pipe coatings, available as solid or foam types, are increasingly used in modern pipeline applications. Solid PU coatings are applied to the inner or outer pipe surface as an alternative to 3-layer external coatings or liquid epoxy for high-abrasion environments. PU foam coatings are applied externally to reduce heat loss and prevent hydrate formation in onshore and subsea gas pipelines. Thanks to their excellent insulation and low thermal conductivity, PU foam coatings help maintain fluid viscosity. In most cases, PU foam is applied over an existing corrosion protection layer such as FBE or liquid epoxy.

Solid PU coating equipment

Solid polyurethane (PU) coatings are applied either by spraying onto rotating pipes or onto pipes moving along a helical conveyor past an airless spray gun. This process requires a fast-curing PU system, ensuring the coating can support the pipe’s weight immediately after application.

PU foam coating equipment

Bauhuis offers a range of PU foam coating solutions. In one method, the pipe is placed inside a jacket with spacers and positioned on a tilting table, where foam is injected from the top to fill the gap between pipe and jacket.

Alternatively, foam can be sprayed directly onto the rotating pipe, after which a polyethylene (PE) film from an extruder is wrapped around it while the pipe moves along the conveyor.

Leak detection options

When required by project specifications, systems for installing heat tracing or leak detection wires can be integrated into the PU foam coating process.